Wamia Muchea Truck Impact Case Study - Heavy-duty Industrial Gate Restoration

12 January 2026

12 January 2026

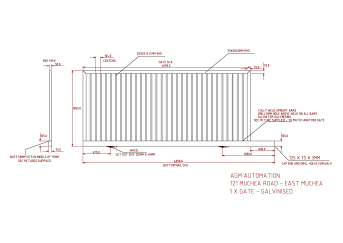

Client: Western Australian Meat Industry Authority (WAMIA)

Location: Muchea, Western Australia

Challenge:

A major industrial facility experienced complete gate system failure following a vehicle impact:

Solution:

AGM Automation implemented a comprehensive replacement programme with industrial-grade components:

Results:

Key Success Factors:

Client Feedback:

The Western Australian Meat Industry Authority expressed satisfaction with the completed installation. The professional project management, quality of materials, and successful restoration of automated access functionality met the facility's operational requirements.

Technical Insights:

Industrial facilities require heavy-duty gate systems with robust automation components designed for high-frequency use and demanding environments. Hot-dip galvanizing provides essential corrosion protection for steel components in industrial settings, ensuring long-term durability and reduced maintenance requirements. HIAB crane deployment is critical for safe handling of heavy industrial gate structures, preventing installation damage and ensuring worker safety. Following significant vehicle impact, comprehensive structural assessment is essential as distorted steel elements cannot be reliably straightened and reused in safety-critical applications. Direct drive motor systems like the FAAC 844 provide reliable performance for heavy industrial gates, with steel gear rack systems ensuring consistent operation under demanding conditions.

If you need help with your logistics electric boom or sliding gate set-up, or wish to automate any other gate configuration, feel free to contact Tim on (08) 9244 8899 to have a no-obligation chat or email tim@agmautomation.com.au for immediate assistance, today!

It depends on the extent of structural damage. Following significant vehicle impact, a professional assessment is essential because distorted steel elements often cannot be reliably straightened and reused in safety-critical applications. Guide posts, gate frames, and automation components may all require replacement if structurally compromised. In some cases, elements like infill panels or guide rollers can be salvaged and refitted, reducing overall replacement costs.

Direct drive motor systems such as the FAAC 844 are well-suited for heavy industrial sliding gates. These motors provide reliable performance under high-frequency use and demanding conditions. When paired with a steel gear rack system, they deliver consistent, smooth operation for large, heavy gates commonly found at industrial facilities, logistics yards, and processing plants.

3. Why is hot-dip galvanising recommended for industrial gate installations?

Hot-dip galvanising (HDG) provides essential corrosion protection for steel gate components exposed to harsh industrial environments. The process creates a durable zinc coating that significantly extends the lifespan of gate frames, posts, and structural elements, reducing long-term maintenance requirements and ensuring the gate remains functional and safe in demanding conditions.

4. How long does it take to replace an industrial gate after truck damage?

Timeframes vary depending on damage severity and gate specifications. The process typically involves initial damage assessment, engineering drawings and design documentation, client approval, fabrication and galvanising coordination, and installation with commissioning. For custom heavy-duty industrial gates requiring specialist fabrication and HDG finishing, expect several weeks from assessment to completed handover, though emergency temporary measures can secure the site during this period.

5. What equipment is needed to install a heavy industrial sliding gate?

Heavy industrial gate installations typically require HIAB-equipped vehicles (crane trucks) for safe transport and positioning of large steel gate structures. This specialist equipment prevents installation damage and ensures worker safety when handling components that can weigh several hundred kilograms. Licensed electrical contractors are also required to connect automation systems and ensure compliance with Australian electrical and safety standards.

Hot-dip galvanising (HDG) provides essential corrosion protection for steel gate components exposed to harsh industrial environments. The process creates a durable zinc coating that significantly extends the lifespan of gate frames, posts, and structural elements, reducing long-term maintenance requirements and ensuring the gate remains functional and safe in demanding conditions

Timeframes vary depending on damage severity and gate specifications. The process typically involves initial damage assessment, engineering drawings and design documentation, client approval, fabrication and galvanising coordination, and installation with commissioning. For custom heavy-duty industrial gates requiring specialist fabrication and HDG finishing, expect several weeks from assessment to completed handover, though emergency temporary measures can secure the site during this period.